- support@ddgear.com

- North 3F, Building 13-2, Zhixin Park, NO.1099 Xianhua South Street, Wucheng, Jinhua, Zhejiang, China.

Products

Custom Precision Gears for CNC Machine | DD Gear

Product Details

FAQ

Features & Benefits

- High positioning accuracy & low backlash:

CNC Machine Gears from DD Gear are designed for low backlash and tight pitch accuracy to support precise spindle speed control, axis feed rates and indexing operations in CNC lathes, machining centers and rotary tables. - Optimized for spindle, feed and rotary drives:

We supply gears for spindle gearboxes, feed gearboxes, rotary tables, indexers and auxiliary drives, taking into account speed range, torque, stiffness and NVH (noise, vibration, harshness) targets for each section of the machine tool. - Wide range of gear types for machine tools:

Custom spur and helical gears, internal gears, gear shafts with integral gears, bevel gears and ring gears allow flexible transmission layouts, from compact headstocks to heavy-duty rotary tables and ATC drives. - Material & heat treatment for fatigue and stability:

Case-hardening alloy steels, nitriding steels and through-hardened alloys are selected to provide high contact-fatigue strength, bending strength and dimensional stability under continuous loading and thermal cycles. - Small-module precision & gear grinding capability:

Where required, ground tooth flanks and carefully controlled runout support low noise, smooth meshing and consistent contact patterns—critical for high-speed spindles and precision rotary axes. - Support for OEM and retrofit programs:

DD Gear can support both new machine-tool platforms and retrofit/modernization projects, producing gears based on existing drawings or measured samples, with prototype-to-series capability and traceable quality documentation.

Technical Specifications

Final data will be defined according to the customer’s drawing and sample.

| Item | Typical Option |

| Gear Type | Spur gears, helical gears, internal gears, bevel gears, ring gears for rotary tables, gear shafts with integral gears |

| Module (m) | Small- to medium-module gears for machine tools |

| Material | Case-hardening alloy steels (such as 16MnCr5, 20MnCr5, 18CrNiMo series), through-hardening alloys (such as 42CrMo4, etc.) and nitriding steels |

| Heat Treatment |

Carburizing and quenching, nitriding, induction hardening, quench and temper; the solution is determined comprehensively based on load, service life, precision and deformation control requirements |

| Surface Hardness | Typically, the tooth surface is hardened to 58–62 HRC (carburized or induction hardened) or as per the drawing requirements; the core toughness is controlled according to bending fatigue requirements and the tooth root safety factor |

| Surface Finish | Tooth flanks the ground or is finely finished where noise and precision are critical; roughness of key journals, holes, and datum surfaces is controlled according to fit and runout requirements |

| Accuracy | Spur/helical gears are manufactured to ISO/DIN/AGMA cylindrical gear accuracy classes; the specific class is agreed upon with the customer based on the spindle/feed/rotary table application. |

Applications

CNC machine gear from DD Gear can be configured for:

- Spindle gearboxes of CNC lathes and machining centers – Spur and helical gears for multi-range spindle speed selection, balancing high speed capability with torque at low speeds.

- Feed gearboxes and axis drives – Gears that transmit motion to ball screws, rack-and-pinion systems or intermediate shafts in X/Y/Z and rotary axes, with low backlash and smooth running.

- Rotary tables and indexers – Precision ring gears and pinions or bevel gear sets for positioning and continuous rotary axes.

- Tool magazine and ATC drives – Spur and helical gears for tool magazine rotation, tool arm motion and indexing mechanisms in automatic tool changers.

- Auxiliary drives – Gears for pallet changers, coolant pumps, chip conveyors and other auxiliary systems integrated into CNC machines.

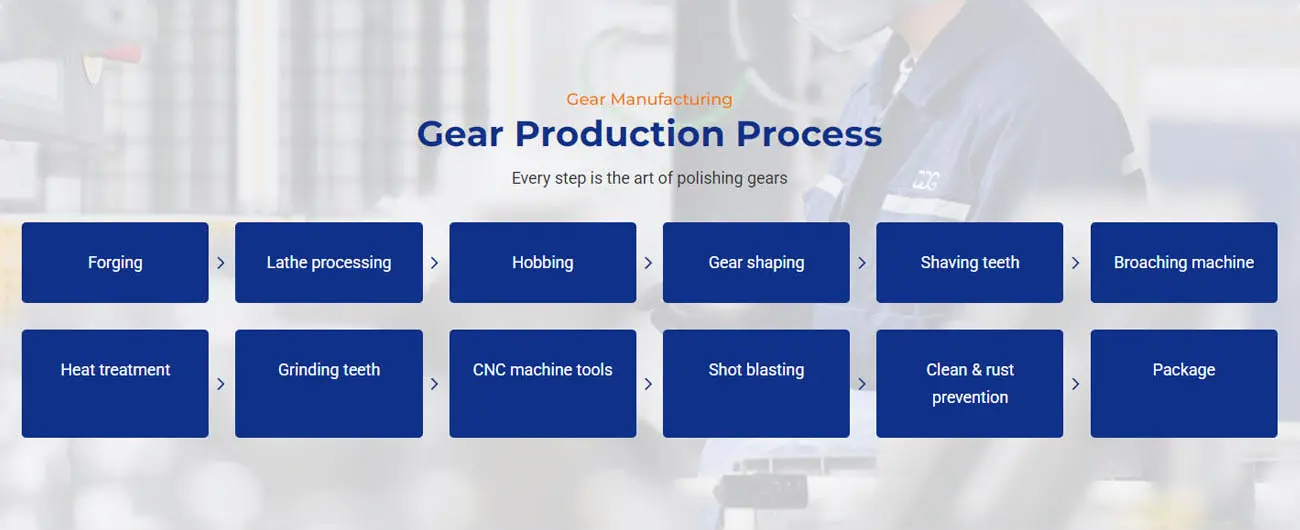

Gear Manufacturing Process

DD Gear applies a controlled, high-precision gear-manufacturing process:

-

Blank preparation – Selection of bar or forged blanks; cutting and rough turning to create reference faces and basic geometry.

-

Turning & pre-machining – Machining of bores, journals, shoulders and faces with allowance for heat treatment and subsequent finishing.

-

Gear cutting – Hobbing or shaping of spur and helical gears; internal gears produced by shaping or broaching; bevel gears cut on suitable bevel gear machinery or multi-axis equipment.

-

Heat treatment – Carburizing & quenching, nitriding, induction hardening or quench & temper according to specified hardness, case depth and distortion limits.

-

Finish machining & grinding – Finish turning or grinding of bores, journals and reference faces to achieve fit and runout requirements; gear grinding or honing of tooth flanks where accuracy and noise targets require it.

-

Deburring & edge conditioning – Chamfering and removal of burrs at tooth edges to reduce stress concentration and prevent contamination of lubrication systems.

-

Cleaning, protection & packaging – Thorough cleaning, rust prevention and packaging adapted to the customer’s assembly and storage conditions.

Precision Gear Customization Process

To support custom CNC machine gear projects, DD Gear follows a clear, eight-step customization process:

Step 1 – Requirement Collection

Customers provide design requirements, 2D drawings, 3D models, or physical samples, together with basic duty cycle information (torque, speed, life, installation).

Step 2 – Drawing Design & Optimization

Based on the provided drawings or samples, DD Gear prepares or optimizes detailed manufacturing drawings and shares them with the customer for confirmation.

Step 3 – Quotation

After the drawings and technical points are confirmed, we issue a precise quotation covering tooling, piece price, lead time, and quality requirements.

Step 4 – Tooling & Fixture Preparation

Once the price is confirmed, we arrange tooling and fixture production. Any tooling cost is agreed with the customer in advance and can be offset or refunded after mass orders, according to the commercial agreement.

Step 5 – First Sample Approval

After tooling and fixtures are ready, we manufacture the first sample batch—typically within about 30 days—and ship it to the customer for testing.The customer inspects and validates the samples in their gearbox or test bench and provides feedback on dimensions, performance, and any required adjustments.

Step 6 – Mass Production

When the sample is approved, we start mass production according to the agreed production plan and quality standards.

Step 7 – Finished Product Inspection

After production, we inspect hardness, dimensions, runout, tooth accuracy, and other critical characteristics to ensure full compliance with the drawing and standards.

Step 8 – Shipping Arrangement

Once inspection is passed and shipment is approved by the customer, we arrange booking, packaging, and delivery to the specified destination.

Quality Assurance & Inspection

DD Gear applies the same quality philosophy to CNC machine gear and all precision gears:

-

Quality management systems based on ISO 9001 and IATF 16949

-

Process control from incoming material to final inspection, including:

-

Material certification and chemical composition checks

-

Hardness and case depth verification after heat treatment

-

Gear measurement for profile, lead, pitch, and runout

-

Surface roughness testing on gear flanks and journals

-

Dimensional inspection with calibrated gauges and CMMs

-

-

Traceability for each batch with inspection records and reports

- Optional documentation such as PPAP/FAIR packs on request

Packaging

Usage & Installation Notes

- Ensure housing and shaft alignment are within design tolerances; misalignment increases noise, wear and can degrade machining accuracy.

- Observe specified fits, tightening torques and mounting procedures for gears, gear shafts and ring gears; avoid forcing components beyond tolerance limits.

- Use the recommended lubrication type, viscosity and filtration level; clean, properly filtered oil is critical for long gear and bearing life in CNC gearboxes.

- Monitor noise, vibration, temperature and backlash changes during maintenance intervals; abnormal trends are a signal to inspect gear contact patterns, lubrication condition and bearing health.

- Protect gears from contamination and corrosion during storage and handling prior to assembly, especially for ground-tooth gears used in precision spindles and rotary tables.

Company Strength – DD Gear

-

Specialized in small module, high-precision gears and shafts for EVs, humanoid robots, AGVs, and intelligent automation.

-

Integrated manufacturing from forging and machining to heat treatment and gear grinding.

-

Quality systems aligned with automotive standards, with experience supporting OEM and Tier 1 projects.

-

Engineering support covering concept feasibility, DFM reviews, and failure analysis feedback.

-

Global export capability with experience serving customers in multiple countries.

Q1: What information do you need to quote CNC Machine Gears?

We typically need: machine type and function (spindle, feed, rotary table, ATC, etc.), 2D drawings and preferably 3D models, gear type (spur/helical/bevel/internal/ring), module and tooth data, material and heat-treatment requirements, shaft arrangement, speed and torque, duty cycle, target accuracy/noise level and annual volume.

Q2: Can you achieve high gear accuracy suitable for CNC machine tools?

Yes. Within the limits of our process capabilities and your design, we can manufacture gears to defined ISO/DIN/AGMA cylindrical gear accuracy classes and agreed bevel/ring-gear tolerances. The required grade will be agreed based on application (spindle, feed, rotary) and cost/performance balance.

Q3: Should I use spur or helical gears in CNC gearboxes?

Spur gears are simpler and cost-effective and can be suitable where noise and vibration are less critical. Helical gears provide smoother engagement, higher contact ratio and generally lower noise and better load distribution, but introduce axial thrust that must be accommodated in the bearing design. The final choice depends on your noise, speed and stiffness requirements.

Q4: Do you supply complete machine-tool gearboxes or only gears and shafts?

DD Gear acts as a precision gear and shaft supplier. We manufacture gears, gear shafts and related components based on your drawings. Complete gearboxes, spindle units and CNC machines are designed and assembled by the machine-tool OEM or system integrators.

Q5: Can you support retrofit or replacement gears for existing CNC machines?

If you can provide accurate drawings or samples that can be measured, we can usually produce replacement gears for existing gearboxes and rotary tables, helping support retrofit, upgrade and service programs. Final fit and performance validation remains the responsibility of the machine owner or integrator.

Reliable precision gears for robotics, automotive, and beyond.

Custom Gears for Sliding, Swing & Industrial Doors | DD Gear

Automatic Door Gear from DD Gear is a range of custom-designed, small- to medium-module gears and shafts used in automatic sliding doors, swing doors, revolving doors and industrial doors (sectional, rolling, high-speed doors). In these systems, compact electric motors drive gearboxes and gear trains that must deliver high starting torque, smooth motion and very low noise while opening and closing heavy door leaves hundreds or thousands of times per day. Typical automatic door operators use one or more stages of spur and helical gears in combination with worm gears or bevel gears. Spur gears provide simple, efficient torque transfer for intermediate stages. Helical gears, with their angled teeth and higher contact ratio, help achieve quieter and smoother running, which is critical in hotels, hospitals, offices and residential buildings. Worm gears are often used for high reduction ratios and self-locking behavior, improving safety when the door is at rest and reducing backdrive from wind loads or manual pushing. In some operators, bevel gears change shaft direction between the motor, transmission and drive shaft or belt/chain. DD Gear manufactures Automatic Door Gears strictly on a custom, build-to-print basis. Using customer drawings or validated samples, we supply spur and helical pinions and gears, worm gears and worm wheels, bevel gears, gear shafts and related components for door operators. Through appropriate alloy steels, surface treatments, controlled heat treatment and precision machining, DD Gear helps door-operator OEMs and system integrators build drives that provide quiet operation, long life and reliable performance in entrances exposed to dust, temperature changes and frequent cycling.

Custom Precision Gears for Electric Wheelchair | DD Gear

Electric Wheelchair Gear from DD Gear covers a family of small-module, custom-designed gears and shafts used in electric wheelchairs, powered mobility scooters and related assistive devices. In these products, compact electric motors drive wheel-side or centrally mounted gearboxes that must deliver high torque at very low vehicle speed, provide smooth, gentle acceleration and braking, and work reliably for years in both indoor and outdoor environments. Typical electric wheelchairs use a single-speed reduction between the high-speed motor and the drive wheel. This reduction is often realized by a worm gear stage, a spur/helical reduction stage, or a planetary gear set integrated into a wheel-side gearbox. Worm gears are commonly used because they can offer high reduction ratios and inherent self-locking behavior in many designs, helping the chair hold position on slopes when the motor is not powered. Spur and helical gears are used in intermediate stages or in designs where efficiency and low noise are prioritized. Planetary gear trains may be used when high torque density and compact packaging are critical, especially in wheel modules. DD Gear manufactures Electric Wheelchair Gears strictly on a custom, build-to-print basis. Based on customer drawings or validated samples, we supply worm gears and worm wheels, spur and helical gears, planetary gear components (sun, planet, ring), gear shafts and wheel-drive gear elements. Using case-hardening steels, controlled heat treatment and small-module precision machining or grinding, DD Gear helps mobility OEMs and system suppliers design drivetrains that offer quiet operation, safe holding behavior, good efficiency and long service life, enhancing comfort and confidence for end users

Custom Precision Gears for Surgical Robotics | DD Gear

Surgical Robot Gear from DD Gear covers a family of small-module, high-precision gears and shafts used in surgical robots, robotic-assisted surgical systems and related medical robotic platforms. In these applications, compact actuators drive robotic arms, wrists, end effectors and instrument modules that must deliver micron-level positioning, smooth motion and highly repeatable force control, often in minimally invasive procedures around critical anatomy. To achieve this, surgical robots commonly use spur and helical gears, planetary gear sets and gears integrated with harmonic or other precision reducers inside joint and instrument actuators. These gear stages must work with high-resolution encoders and advanced control algorithms, providing low backlash, high torsional stiffness and consistent friction characteristics across the full range of motion. At the same time, many components operate near the sterile field and must tolerate frequent cleaning and sterilization cycles, use biocompatible or low-outgassing materials and lubricants, and minimize particle generation. DD Gear manufactures Surgical Robot Gears strictly on a custom, build-to-print basis. Based on your drawings or validated samples, we supply spur, helical and bevel gears, planetary components (sun/planet/ring), gear shafts, small-module pinions and interface gears for precision reducers, using carefully selected alloy steels, stainless steels and, where specified, non-magnetic or corrosion-resistant materials. With controlled heat treatment, precision machining and (when required) ground tooth flanks, DD Gear supports surgical robot OEMs and system suppliers in building actuators that deliver precise, smooth and reliable motion, while supporting cleaning and sterilization concepts defined at the system level.

Custom Precision Gears for Automated Guided Vehicles | DD Gear

AGV Gear from DD Gear refers to a range of custom, small-module gears and shafts specifically engineered for Automated Guided Vehicles (AGV) and Autonomous Mobile Robots (AMR) used in warehouses, factories, distribution centers and logistics hubs. In these applications, compact electric motors drive wheel-mounted or centrally mounted gearboxes that must deliver high torque at low travel speed, provide smooth, precise motion control, and withstand continuous start/stop cycles in 24/7 intralogistics operations. Typical AGV drivetrains combine motor + reduction gearbox + drive wheel, often in a wheel hub or wheel-side gearbox design, while steering and lifting functions may use additional gear stages or screw drives. Single- or multi-stage spur and helical gears are common in wheel drives and intermediate stages, while planetary gear sets are widely used where high torque density and compact packaging are required, such as in drive wheels for heavy loads or AGV forklifts. In some architectures, gears are also combined with chain or belt stages to reach the final wheel or mast. Compared with traditional industrial vehicles, AGV/AMR systems place greater emphasis on low noise, smooth operation, positioning accuracy and long maintenance intervals. DD Gear manufactures AGV gears strictly on a custom, build-to-print basis, supplying spur and helical gears, planetary gear components (sun/planet/ring), bevel gears, gear shafts and wheel-drive gear elements based on customer drawings or validated samples. Using case-hardening steels, controlled heat treatment and small-module precision machining or grinding, DD Gear supports AGV and AMR OEMs in building transmissions that provide high efficiency, compact size, low NVH and long service life in demanding indoor and outdoor logistics environments.

Custom Reduction Gears & Shafts for E-Motorcycle | DD Gear

E-Motorcycle Gear from DD Gear refers to a range of small-module reduction gears and shafts engineered for electric motorcycles, e-scooters, e-mopeds and high-power e-bikes. Instead of multi-speed gearboxes like those used in traditional ICE motorcycles, most electric two-wheelers use a single-speed reduction between the high-speed electric motor and the wheel. This reduction can be realized by hub-motor planetary gear sets, mid-drive spur/helical gear stages, or a combination of gear reduction + chain or belt drive. In hub-motor architectures, a compact planetary gear train is often integrated inside the wheel hub to reduce motor speed and increase wheel torque while keeping unsprung mass and noise under control. In mid-drive or centrally mounted motor layouts, the motor drives an intermediate shaft via spur or helical gears, and torque is then transferred to the rear wheel by a chain or belt. In both cases, the gears must handle high input speeds, frequent acceleration/deceleration, high torque at low road speed, outdoor exposure and strict NVH requirements, all within tight packaging envelopes. DD Gear manufactures E-Motorcycle Gears strictly on a custom, build-to-print basis. Using customer drawings or validated samples, we supply spur and helical pinions and gears, planetary gears (sun/planet/ring), gear shafts and hub-motor gear components. With appropriate case-hardening steels, controlled heat treatment and small-module precision machining or grinding, DD Gear helps electric two-wheeler OEMs and system suppliers build drivetrains that deliver high efficiency, quiet operation, compact packaging and long service life, supporting both urban commuting and higher-performance applications

Custom Precision Gears for Packaging Machinery | DD Gear

Packaging Machinery Gear from DD Gear is a family of small- to medium-module, custom-designed gears used in form-fill-seal (FFS) machines, cartoners, case packers, palletizers, labelers and conveyor systems. In modern packaging lines, gears are responsible for coordinating motion between film feed, sealing jaws, product infeed, carton erection, filling, closing and outfeed. They must operate at high speed, often in 24/7 duty, while maintaining precise timing and position to avoid film waste, misaligned seals, product jams and unplanned downtime. Most packaging mechanisms rely on spur and helical gears in gearboxes and timing stages for parallel shafts. Spur gears provide simple, highly efficient torque transmission and are widely used in indexing, feed and cam drives. Helical gears, with their angled teeth and higher contact ratio, offer smoother, quieter running and higher load capacity, which is important in high-speed packaging halls where noise and vibration affect both productivity and operator comfort. In right-angle or compact layouts, bevel gears, worm gears or planetary sets may be used to change direction or achieve higher reduction ratios in a limited envelope. DD Gear manufactures Packaging Machinery Gears strictly on a custom, build-to-print basis. Based on your drawings or validated samples, we supply precision spur, helical, bevel gears, gear shafts and internal gears, using case-hardening steels, nitriding steels, stainless or corrosion-resistant grades, and selected engineering plastics where appropriate. Through controlled heat treatment, finishing and systematic quality control, we help packaging OEMs and retrofitters build gear trains that deliver stable speed ratios, smooth motion, low noise and long service life, even in demanding environments involving dust, humidity or washdownExploring The Science of Precision Gears

Top 7 Factors Every Business Must Consider When Ordering Custom Gears

In the fast-changing world of factory automation, electric transport, and exact robotics, one mechanical part’s work can decide how dependable a whole setup becomes. This holds true for quick electric car drive systems or tiny robot arms in surgery. The precision gear setup acts as the quiet core for movement. Companies looking for top results often find standard parts hit their limits. So, a made-to-order design method turns out vital. At DD Gear, we focus on services that turn tough design needs into strong working parts. Good results in any customized precision gear task come from a solid grasp of how metal types, shapes, and specific use limits work together. Application-Specific Tooth Geometry and Micro-Geometry Picking the tooth shape stands as the first key choice in any customized work. Studies show that various shapes handle different running issues: Spur Gears: These have straight teeth along the axis. They give high output, reaching up to 98%, and create no side forces. Such precision gears fit well for cost-aware jobs at normal speeds. Helical Gears: High-precision helical gearsets for EV reducers have teeth cut at an angle to connect step by step. This cuts down on noise, shaking, and the rough feel a lot. They also handle bigger loads because more teeth touch at once. Micro-Geometry Modifications: For top-level work, builders need to think about small shape changes. Methods like tip relief, crowning, and root easing make up for bending under force. These customized tweaks keep contact even when shafts bend from strong twists. Material Selection and Metallurgy A precision gear lasts only as long as the metal used to make it. Selecting the right mix means finding a balance between hard surfaces and tough insides: High-Load Alloy Steels: Choices like 18CrNiMo7-6 high-load carburizing gear steel and 20MnCr5 serve as common picks for strong customized precision gear groups. They offer a fine mix of power and hit resistance. Core vs. Surface: A top customized precision gear needs a firm outside, often 58–62 HRC, to fight wear and dents. At the same time, it keeps a bendable center at 35–45 HRC to take in quick heavy hits. Forging vs. Bar Stock: Forging lines up the metal grains with the tooth form. This can raise wear life a good deal over simple bar stock. For more on how various metals hold up under repeated stress, check Machine Design. Precision Heat Treatment and Surface Hardening The final work of customized precision gears gets set during heat steps. The way chosen must fit the job’s force and exactness needs: Carburizing: This builds thick, hard layers, up to 1.2 mm, and works best for tough jobs like drive wheels in automated carts or electric car gearboxes. It gives the most fight against surface wear. Nitriding: This is suitable for exact parts where little shape change matters most. It runs at a lower heat, so it holds tight measures without the twist risks from quick cooling. Controlled Case Depth: In customized high-twist setups, the layer depth stays within 0.05 mm. This keeps things steady across big making runs. Accuracy Grades and Global Standards Exactness goes beyond just a sales word. It stands as a clear measure that shapes power use and lasting time. ISO 1328 Standards: Exactness falls into levels, with Grade 1 as the best. For key fast jobs, customized precision gears often need to achieve ISO 1328 Grade 4 precision ground gears standards. Efficiency Gains: Moving from basic Grade 7-8 to fine Grade 4-5 can raise drive setup output by up to 1.2%. In group operations, this means big power savings and longer reach on batteries. Verification: Strong customized tasks must get checked on computer-controlled gear tools to keep form errors under 4 μm. Rules for tight motion control often come from the National Institute of Standards and Technology (NIST). Backlash Control and Torsional Stiffness In robotics and machine tools, spot-on placement cannot be bargained away. Zero-Backlash Requirements: For robot links, any loose space in the gear line leads to shakes and wrong paths. Low-backlash precision gears for humanoid joints prove key for steady hold in parts like hips and elbows. Torsional Stiffness: Good customized pieces must resist twist under force. This stops end tools from shifting and keeps repeated spots within ±0.02 mm. Lost Motion: Cutting lost motion makes control inputs reach the end without delay from loose parts. Noise, Vibration, and Harshness (NVH) Reduction As fields shift to electric power, implementing low – NVH quiet-running small-module precision gear solutions becomes essential as there’s no motor roar to hide machine whines. Transmission Error (TE): Gear sounds often start from small tooth side flaws. Shifts of just a few microns can make loud whines at speeds above 10,000 RPM. Decibel Targets: Forward customized plans for storage robots aim for sound levels around mid-50 dB. This keeps workers at ease in spots with people and machines. Surface Finish: Reaching a rough level of Ra 0.4 μm or finer proves important for quiet runs in high-end electric cars. Integration and Packaging Constraints Current machines grow smaller and stronger, which calls for customized answers that squeeze into tight spots. Torque Density: High torque density planetary gears for AGV wheel-hub drives often pack high twist force into areas as small as a coffee cup. Small-Module Precision: The move to tiny modules, from 0.3 to 0.8, lets builders fit big cut ratios into small drive cases. Drop-in Upgrades: Many firms need customized gear groups that act as direct swaps for old parts. They keep the same case sizes but boost work levels. The DD Gear Advantage: Mastering Customized Precision DD Gear started in 2010 to focus on fine, small module precision gears for new fields. With more than 15 years in the trade and ISO 9001/IATF 16949 marks, we deliver customized precision gear answers that stay “Drive & Durable”. Our customized making process includes: Requirement Collection: Reviewing your 2D drawings or actual samples. Optimization: Drawing and tweaking plans for the best output. Fast Prototyping: Sending fine samples in just 2–3 weeks. Mass Production: For high-performance projects, we can achieve up to ISO 1328 Grade 4–5 accuracy, 100% detection of key features and batch verification. The specific plan is defined according to the project. Contact DD Gear Today to develop a custom small-module precision gear solution tailored to your exact torque, noise, and space requirements. FAQ Q: What is the primary cause of gear noise at high speeds? A: Gear noise is typically caused by transmission error resulting from minute tooth flank deviations. At speeds over 10,000 RPM, deviations of a few microns can create a significant whine. Q: Why are small-module gears necessary for modern robotics? A: They help designers fit large torque and high reduction ratios into very compact spaces, preventing the gearbox from taking up too much room in the machine. Q: What materials does DD Gear recommend for high-cycle environments? A: We typically use case-hardened alloy steels like 18CrNiMo7-6 or 20MnCr5, which provide a hard exterior to fight wear and a tough interior to absorb shock loads. Q: Can you provide customized gears for medical applications? A: Yes, we offer non-magnetic austenitic stainless steel gears for MRI equipment for MRI-adjacent modules.

Exploring the Precision and Power Behind High-Precision Gears

In the field of current engineering, machines now move more quickly, with more strength, and in tighter spaces. From robots in surgery that handle tiny adjustments to electric cars running quietly on fast roads, the heart of these setups lies in high-precision gear groups. At DD Gear, we know that a quick motor’s full potential rests on the high-precision gear systems that handle its push. These customized precision gears for robotics link raw electric force to steady physical action, acting as the silent support in automated setups. The Theoretical Foundation of Gear Performance The close work between motors and gears matters a lot for good results. Modern electric motors often spin past 15,000 RPM, but these turns are usually too rapid for straight use. Precision gear groups, like small-module precision gears for electric vehicles,change fast, weak twist into the managed speed and strong twist needed for real tasks. The Shift to Small-Module Precision As factory tools get smaller but tougher, the need for small-module precision gears for electric vehicles grows sharply (typically modules 0.3 to 0.8), offering solid torque in compact spaces. Torque Density: High-precision planetary gearsets deliver solid torque in small areas, which suits robot joint drives and AGV wheel hubs well. Micron-Level Tolerance: Thinner teeth allow little room for mistakes. A shift of just a few microns in the tooth shape can lead to strong noise or a quick breakdown in fast uses. Integrated Design: Current engineering often calls for combined gear-shaft parts to cut down on connections and boost straightness in small motor builds. Mechanical Efficiency and Energy Conversion Precision gear sets for industrial automation go beyond just fitting; they deal with handling power efficiently, ensuring minimal energy loss, especially in systems like high-torque gear reducers for heavy-duty applications. Efficiency Retention: Top gear systems, especially in EVs, keep power losses low. A drop of only 1% in a slowdown setup can cut a car’s battery travel by 4–8 km. Torque Multiplication: Slowdown gear systems turn quick spins into the firm pull required for heavy starts and climbing slopes. Core Gear Classifications and Engagement Mechanics Grasping the shape of tooth contact is key to setting the output of a drive system, particularly in low-backlash planetary gear drives, which are essential for achieving smooth operation in high-speed motors. Parallel Shaft Gears: Spur vs. Helical Spur Gears: With straight teeth sliced even to the gear line, spur gears give basic shapes and strong output (94%–99%). Yet, since the teeth meet all together, they can make harsh sounds and shakes at quick paces. Helical Gears:These gears hold teeth sliced at a slant, which lets contact build slowly. This even shift cuts down Noise, Vibration, and Harshness (NVH) a great deal, so they stand as the top pick for fast helical gear reducers in passenger EVs and health tools. Intersecting and Crossed Axis Gears Spiral Bevel Gears: Applied to pass motion between crossing shafts (often 90°), these gears rely on bent teeth to offer better touch rates and bigger load holding than straight bevel gears. Worm Gear Sets: Made of a thread-like worm and a toothed ring, these sets reach very high slowdown rates (up to 100:1) in tight spots and give built-in self-stop traits for safety. For further reading on the calculation of internal gear load capacity, you may refer to the technical guidelines provided by the ISO 6336-1:2019. Material Science and Micro-Geometry Optimization High-precision output comes from better metalwork and tiny shape tweaks. Advanced Metallurgy for Durability Advanced metallurgy for durable gears begins with high-quality alloy steels like case-hardening steel for heavy-duty gears, ensuring both high surface hardness and shock absorption. 18CrNiMo7-6 & 20MnCr5: These serve as usual hardening steels used in heavy planetary and car gearboxes. They bring high outer hardness (HRC 58–62) while keeping a sturdy, flexible inside. Non-Magnetic Options: For special uses like MRI scan systems, gearsets come from tailored materials such as aluminum bronze or austenitic stainless steel to stop magnetic mix-ups. Micro-Geometry Modifications for Acoustic Excellence In quiet settings, basic cutting falls short. Minor shifts, often just microns thick, get added to tooth faces: Tip Relief and Crowning: These fixes make sure teeth enter and leave smoothly, balancing out growth from heat and stopping force pile-up at sides. Lead Corrections: These shifts spread torque evenly over the gear face, stretching work life in high-turn jobs. Super-finishing: Exact grinding can reach surface roughness of Ra 0.4 μm or smoother, which lowers the rub and cuts out sound causes. To explore the standards of measurement required to verify such sub-micron accuracies, consult the resources at the National Physical Laboratory (NPL). DD Gear: A Specialist in Customized Precision Solutions With more than 15 years in the field, DD Gear has built a spot as a world leader for coming industries. We specialize in providing custom gear solutions for AGV and robotics, focusing on made-to-order and build-to-print jobs where exactness and durability matter most. Our Core Manufacturing Capabilities We run ISO 9001 and IATF 16949 approved sites, using top CNC gear and Klingelnberg or Reishauer grinders to aim for ISO Grade 4–5. Our making steps include: Hobbing and Shaping: Quick cutting for different tooth shapes. Precision Tooth Grinding: Reaching the very smooth faces needed for low-sound fast inputs. Controlled Heat Treatment: Exact carburizing and nitriding to keep even case depth and hardness. Specialized Customized Services for Emerging Industries DD Gear acts as a design helper, aiding makers in crafting the right drive for their exact work rounds. Robotics: We supply low-backlash planetary gear drives and tailored joint actuators for humanoid and factory robots, ensuring smooth performance in advanced applications. Electric Vehicles: Our skills cover high-precision e-axle gear parts and fast rotor shafts balanced to G1.0 standards. AGV & Logistics: We build lasting, tailored small-module planetary drives for storage robots, making sure they hold up in round-the-clock runs. Rapid Prototyping: We back quick job times by sending tailored gear prototypes in 2–3 weeks. From the joints of a walking robot to the high-torque reducers of a city bus, if a motion system demands silence, strength, and precision, DD Gear delivers the customized components that drive the future. Unlock the power of precision gears. Contact DD Gear today to explore custom solutions for your robotics, EV, and industrial applications. FAQ Q: What gear accuracy levels can DD Gear guarantee? A: We aim to achieve ISO 1328 Grade 4–5 accuracy for high-performance applications, verified using CNC gear measuring machines. Q: Do you support small-volume customized orders and prototyping? A: Yes. We offer flexible Minimum Order Quantities (MOQs) and typically deliver customized gear prototypes within 2–3 weeks. Q: What is the main cause of gear noise in high-speed applications? A: Tiny shape errors on the tooth flank can cause teeth to “bump” instead of rolling. At speeds over 10,000 RPM, errors of just a few microns result in a noticeable whine. Q: Which materials are most common for high-load, high-precision gear sets? A: We primarily use high-strength case-hardening steels like 18CrNiMo7-6 and 20MnCr5 to achieve high surface hardness with a tough, shock-absorbing core. Q: Why are helical gears often preferred over spur gears in EVs? A: Helical teeth sit at an angle and mesh gradually, which significantly reduces the high-pitched whine common in high-speed electric motors.

How Precision Spur Gears Enhance High-Efficiency Transmission Systems

In today’s high-performance engineering field, systems must deliver greater speed, handle more power, and fit into smaller packages than ever before. Precision spur gears sit at the heart of these designs. They appear in high-speed electric motors turning at 15,000 RPM and in surgical robots that demand accuracy measured in microns. At DD Gear, we know that although spur gears rank among the simplest gear types, advances in manufacturing have turned them into key elements for reaching top mechanical efficiency within very limited space. Theoretical Foundations of Spur Gear Transmission High-efficiency spur gear transmission systems feature straight teeth cut parallel to the axis of a cylindrical body. These precision gears are key components in driving high-torque gear sets for AGVs, ensuring smooth and reliable operation. They transmit motion and power between parallel shafts and provide a steady, accurate speed ratio with straightforward construction. Engagement Mechanics and Efficiency The main strength of spur gears comes from their contact behavior. They rely mostly on rolling action along the tooth curve rather than sliding. That rolling reduces friction losses considerably. When properly designed and made with care, high-efficiency spur gear transmission systems commonly achieve mechanical efficiency between 94% and 99% in a single stage, especially when combined with low-backlash planetary gear drives for smoother motion. Advantages in High-Efficiency Systems No Axial Thrust: The parallel tooth arrangement produces no sideways force along the shaft. Bearing setups stay simpler, and the overall assembly weighs less. Direct Power Transfer: Straight teeth pass force in a direct path. This suits applications where high efficiency matters at moderate speeds and cost remains a concern. Compact Coaxial Layouts: Spur gears fit neatly into planetary systems. They support high torque output from small volumes. Design Parameters for Optimal Efficiency Engineers concentrate on several key factors to reach the highest possible efficiency in modern transmissions. The Shift to Small-Module Precision New equipment often calls for large reduction ratios inside very tight spaces. Demand has grown quickly for small-module precision gears for electric vehicles, usually ranging from module 0.3 to 0.8. These gears enable complex power conversion in compact spaces, critical for planetary gear sets for compact systems. Fine teeth enable complex power conversion in housings no larger than a standard coffee mug. Micro-Geometry Modifications Basic tooth shapes sometimes fall short in demanding applications such as advanced robotics or modern electric drivetrains. High-performance gears depend on small adjustments to the tooth form for quiet running and smooth performance: Tip Relief: Slight rounding at the tooth tips promotes gentle entry and exit during meshing. Crowning: A mild curve along the tooth face prevents concentrated loads at the edges and lengthens working life. Lead Corrections: Small changes distribute torque more evenly across the face and reduce early wear. For deeper technical information on how these tooth modifications lower transmission errors, refer to Gleason, a worldwide authority in gear technology research. Material Durability and Heat Treatment Dynamics The long-term performance of any drivetrain depends directly on precision gear durability. Each tooth must withstand repeated bending at the root and high contact pressure millions of times during service. Metallurgy and Alloy Selection Precision spur gears designed for heavy loads usually start as forged bars of high-grade alloy steels. Common choices for demanding transmissions include: 18CrNiMo7-6 & 20MnCr5: Case-hardening steels that develop a very hard, wear-resistant surface over a strong, flexible core. SCM415 & SCM420: Frequently selected for electric tools and bicycles because they resist surface fatigue well. Precision Heat Treatment Standards Precision heat treatment for high-load gears, such as carburizing for high-load gears, creates a hard outer layer that resists contact fatigue, making gears more durable for heavy-duty applications. Nitriding offers an alternative for lighter stages where shape stability matters most, since it hardens the surface with almost no distortion. Process Typical Hardness Advantage Carburizing 58–62 HRC High load capacity and wear resistance. Nitriding 800–1100 HV Minimal distortion, preserving tight tolerances. Induction Hardening 50–58 HRC Rapid heating, controllable hardened layers. DD Gear: Pioneering Precision in Transmission Systems Founded in 2010, DD Gear has spent more than 15 years specializing in high-efficiency motion components. We specialize in custom gear solutions for robotic actuators, providing high-performance alloy steels for gears and meeting the strict requirements of industries such as robotics, automotive, and medical tools. Our production meets ISO 9001 and IATF 16949 standards. That certification confirms every part satisfies the strict quality demands of major OEMs in automotive and robotics markets. For critical applications, we can achieve up to ISO 1328 Grade 4–5 accuracy, verified on Klingelnberg P26/P40 gear measuring machines. The Value of Customized Precision Gear Solutions DD Gear does not offer a standard catalog. We maintain that true high-efficiency transmission comes only from parts tailored to the specific duty cycle and space limits of each application. Why Choose Customized Engineering Application-Specific Optimization: Off-the-shelf gears often miss the mark on NVH targets or zero-backlash needs in areas such as medical imaging equipment and humanoid robotics. Flexible Production Volumes: Our shop handles single prototypes through medium runs. We avoid the rigid batch sizes common in large-scale plants. Rapid Prototyping: Prototype gear sets typically arrive within 2–3 weeks, which supports tight project schedules. Build-to-Print Precision: We manufacture directly from client drawings. Complex integrated gear-shaft designs reduce assembly joints and improve overall alignment. Industry-Specific Applications of Precision Spur Gears Precision spur gears provide the quiet strength behind many advanced machines. Robotics and Automated Guided Vehicles (AGVs) Spine gear design for humanoid robots demands precision and accuracy, with custom gear solutions for robotic actuators ensuring high repeatability in complex movements. Custom low-backlash spur gears and planetary sets with sub-micron profile precision keep motion consistent and repeatable. In warehouse AGVs, case-hardened spur gears handle sudden torque jumps up to 600 Nm without developing surface damage. Electric Vehicles (EV) and E-Axles Helical gears often get chosen for lower noise, but precision spur gears appear frequently in intermediate reduction stages of EV gearboxes. There, efficiency and cost matter most. Advanced grinding produces a surface finish of Ra 0.4 μm. That smooth finish cuts internal losses and helps extend battery driving range. Medical and Professional Tools Surgical robots depend on vibration-free motion for precise work. Professional power tools face rough handling on job sites, yet must last through heavy use. DD Gear’s custom solutions deliver the consistent performance required for these high-duty applications. Elevate your gear systems with DD Gear’s precision engineering. Contact us today for custom spur gears tailored to your specific needs in robotics, automotive, and medical applications. We offer rapid prototyping and flexible production volumes to fit your project timelines. FAQ Q: What accuracy levels can DD Gear achieve for customized spur gears? A: We aim for ISO 1328 Grade 4–5, with the final accuracy defined by customer drawings and specific application requirements, supported by high-precision CNC grinding and Klingelnberg P-series inspection systems. Q: Does DD Gear support small-volume orders and prototyping? A: Yes. We offer flexible MOQs and provide customized prototyping services with a typical lead time of 2–3 weeks. Q: Which materials are best for high-load spur gear transmissions? A: We primarily use high-performance alloy steels like 18CrNiMo7-6 and 20MnCr5 to ensure a wear-resistant surface and a shock-absorbing core. Q: Why is small-module design essential for modern gearboxes? A: Small modules (0.3–0.8) allow for extremely high reduction ratios in compact spaces, which is critical for lightweight EV drivetrains and robotic actuators.

The Ultimate Guide to Worm Gears: Types, Applications, and How to Choose

Have you ever wondered how a big industrial lift holds steady even when power fails, or how a small robot arm gets strong torque in a spot no bigger than a coffee mug? The reason is often the quiet, strong work of the worm gear. At DD Gear, we have spent over 15 years perfecting custom precision worm gears, focusing on high-torque worm gears and precision gearing solutions for a variety of industries. We know that picking the right transmission part can make a system run smoothly or break down too soon. This guide looks at the basic ideas and real-world tips for precision worm gears to help you improve your next engineering job. Understanding the Mechanics: What is a Worm Gear A precision worm gear set is a special kind of right-angle drive made up of two main pieces: a high-torque worm gear and a worm wheel designed for precision applications. Unlike regular spur or helical gears that mostly use rolling contact, the worm’s thread slides against the wheel’s teeth in a steady way. The Core Components The Worm: This drives the system, looking like a threaded rod, much like a bolt. In precise work, people often make the worm from case-hardened alloy steel to handle heavy sliding friction. The Worm Wheel: Also called the gear, this meshes with the worm. To cut down on friction and wear from sliding, the wheel usually comes from softer materials that lubricate themselves, such as phosphor bronze or tin-bronze alloys. The Right-Angle Advantage One key feature of this setup is the 90-degree angle between the shafts. That lets engineers fit high reduction ratios into tight spaces, which matters a lot for current robotics and small automated setups. Key Characteristics and Performance Benefits People pick precision worm gears for traits that other types, like spur or bevel gears, just can’t match. High Single-Stage Reduction Ratios High-torque worm gears are ideal for slowing speed and boosting torque, providing reliable performance for industries requiring robust mechanical systems.While normal gear sets might need several stages for high ratios, one precision worm gear pair can give ratios from 20:1 up to 100:1. This makes the drivetrain simpler, with fewer parts and less chance of breakdowns. Inherent Self-Locking Capability Maybe the most useful trait of a worm drive is the self-locking effect. When the worm’s lead angle stays small enough, the friction between the worm and the wheel gets so strong that the wheel can’t turn the worm back. This acts as a natural brake, a key for safety in things like: Vertical hoists and lifts. Automated gates and security barriers. Precision valve actuators that must hold position under pressure. Smooth and Quiet Operation Precision worm gears for medical equipment are known for their low-noise operation, ideal for settings where vibration and sound need to be minimized. This makes them a good pick for places where noise, vibration, and harshness need to stay low, like hospitals, offices, or fancy home elevators. For more on the math behind gear noise and vibration, check out spots like the Journal of Mechanical Design. It explains how tooth shape affects sound levels. Material Science and Durability How long a high-efficiency precision worm gear set lasts depends a lot on how the two different materials work together for the worm and the wheel. Optimized Material Pairing To get a long working life, the harder worm runs against a softer wheel. Hardened Steel Worms: Using alloys like 20MnCr5 or 18CrNiMo7-6, the worm sides get hardened to 55–62 HRC through carburizing and quenching. Bronze Worm Wheels: Bronze gives good slipperiness. Under big loads, the bronze bends a bit to form a better contact area, which spreads out the sliding stress more evenly. Efficiency Considerations Keep in mind that sliding creates more heat than rolling in helical gears. Precision worm gear efficiency usually falls between 50% to 90%. Bigger reduction ratios often mean lower efficiency because of more friction from steeper lead angles. Good lubrication with thick oils and extreme pressure additives helps keep performance steady. Diverse Applications Across Industries Precision worm gears are widely used in fields such as robotics, medical equipment, and automotive applications, where high-torque performance and compact designs are crucial. Robotics and Positioning Systems In humanoid robotics and automated tables, worm drives offer the strong holding torque and even motion for steady joint action. They can keep a spot without ongoing motor power, so they cut energy use in robots that run on batteries. Medical Equipment Dependability and quietness matter most in medical settings. Precision worm gears show up in: Surgical Robots: For steady force control and positioning down to microns. Imaging Systems: Moving patient tables side to side or up and down near MRI and CT machines. Automotive and Logistics From steering parts and seat adjusters in electric cars to fast drive units in Automated Guided Vehicles (AGV), precision worm gears deliver power in tight spots. For details on how these gears work in new electric mobility, the SAE International site has lots of studies on transmission performance. How to Choose: Selection and Customized Design Picking the right gear set balances ratio, room, and surroundings. Since each machine has its own load and speed needs, custom precision worm gears for high-load systems often offer better performance than ready-made parts, especially when sound or lifespan is a critical factor. Key Selection Criteria Target Ratio: Set the needed speed drop. Keep in mind that higher ratios might boost self-locking but cut overall efficiency. Center Distance and Alignment: Accuracy counts. Just a few microns off can speed up wear on the bronze wheel. Duty Cycle: Will the gear work all day in a shipping center, or just now and then in a medical tool? Heavy-use jobs need deeper hardening and better surface finishes (Ra 0.4 or finer). The Case for Customized Engineering Mass-produced standard items suit basic machines, but custom precision worm gear solutions for small spaces or specific performance goals, such as quiet operation worm gears for medical robotics, are key for top systems. A customized method lets you: Adjust tooth shapes finely to reduce noise and vibration. Choose certain alloy steels for big-load drives. Match materials (like specific phosphor bronze grades) for long-lasting use in many cycles. DD Gear: Your Partner for Precision At DD Gear, custom precision worm gears is an important direction for our small module precision gears for medical equipment, robotics, and automation. We don’t keep stock items; instead, we team up with worldwide makers to turn detailed 2D/3D drawings into reliable mechanical components. Why Choose DD Gear? Proven Expertise: Over 15 years of delivering customized gears to more than 30 countries. Certified Quality: Our plants hold IATF 16949 and ISO 9001 certifications, making sure every gear hits high automotive and industrial standards. Advanced Capabilities: With Reishauer and Klingelnberg grinders, we aim to reach ISO Grade 4–5 accuracy. Fast Iteration: We make customized prototypes in as little as 2–3 weeks, so your group can check designs quickly. Whether you build a surgical robot or an e-axle for a car, our team stands ready to help from start to full production. Contact DD Gear today to discuss custom precision worm gears tailored to your torque, space, and performance needs. FAQ Q: Can worm gears be used for high-speed applications? A: They can take high input speeds, but sliding contact makes a lot of heat. For speeds above 10,000 RPM, careful grinding and special lubrication stop overheating. Q: Does DD Gear support small-volume customized orders? A: Yes. We have flexible minimum order quantities and quick prototyping for customized sets, often shipping in 2–3 weeks. Q: Are worm gears always self-locking? A: Not always. It depends on the lead angle and material friction. We can shape customized designs to stress either better self-locking or higher efficiency. Q: What materials are best for heavy-duty worm gears? A: We mainly use strong case-hardening steels like 18CrNiMo7-6 for the worm and tough tin-bronze for the wheel to fight wear best.

How Precision Planetary Gears Improve Torque and Efficiency in Power Tools

In today’s field of industrial design, people want power tools that are smaller, lighter, and yet more powerful. This applies to items like high-torque impact drivers or precise surgical drills. The tool’s performance relies on the mechanical core that turns motor speed into useful force. At DD Gear, we have worked for more than 15 years on the theory and hands-on aspects of high-torque planetary gears, focusing on custom precision planetary gears for power tools and other high-performance applications.. We have seen directly how switching to planetary systems has greatly improved the output and dependability of handheld devices. This guide looks into the engineering basics of precision planetary gears and explains why they stand out as the better option for top-performing power tools. The Theoretical Foundations of Planetary Gearing To understand why custom precision planetary gear systems lead in the power tool sector, you need to look at their unique setup, which offers higher torque density and better efficiency. Unlike regular parallel-shaft spur or helical gears, a planetary (or epicyclic) gear set uses a coaxial design. The Core Epicyclic Architecture A typical planetary system includes four main parts that operate together: The Sun Gear: Placed in the middle, it acts as the main input from the fast-spinning electric motor. The Planet Gears: Several gears that circle the sun gear and connect with an outer ring. The Ring Gear: A gear on the inside that stays still or turns to give the last speed reduction. The Planet Carrier: The frame that supports the planet gears and passes the total torque to the output shaft. Coaxial Alignment and Space Efficiency The biggest basic benefit of this arrangement is its compact, coaxial layout. Since the input and output share the same line, designers can pack big reduction ratios into a tube-shaped case that fits the tool’s motor and grip. This space-saving feature is the main reason current cordless drills stay easy to handle while providing huge torque. The Mechanical Advantages for Power Tool Performance The shift from basic gear trains to precision planetary systems comes from various mechanical factors that affect how users feel and how long the tool lasts. High Torque Density through Load Sharing In a standard gear pair, the load sits on just one tooth contact at a time. But planetary gears spread the load over several planet gears all at once. Simultaneous Meshing: With three or four planets dividing the torque, the pressure on each tooth drops a lot. Increased Capacity: This allows a compact planetary gear setup to manage the same torque as a larger spur gear, making it ideal for small-module precision planetary gear sets in handheld tools. Efficiency and Energy Conservation Today’s battery-operated tools focus on saving energy to extend the use time per battery. Precision planetary gear systems run efficiently, usually hitting the 94–99% efficiency range per stage. They reach this through smooth rolling contact and even forces inside the gear set. So, more power from the motor gets to the chuck instead of turning into wasted heat. For more details on mechanical power transfer efficiency, check out sites like Machine Design. Smoothness and Low NVH (Noise, Vibration, Harshness) Fast electric motors in tools often run at 12,000 to 15,000 RPM. At those speeds, small tooth issues can lead to a loud whine or shaking. Contact Ratio: Precision planetary gear sets provide a higher contact ratio, so more teeth touch at the same time, which results in smoother action. Acoustic Stability: The even orbit of the planets cuts down on side vibrations. This matters a lot for user comfort and the tool’s overall feel of quality. Material Science and Precision Engineering The basic gains from a precision planetary gear only show up if the parts are made to tight specs and toughened to handle the sudden stresses of building work or metal shaping. Alloy Steels and Case Hardening Durable precision planetary gears for high-torque applications need a mix of hard outer layers and strong inner cores to prevent tooth snaps during rapid stops, as seen in drills and grinders. Steel Selection: Top-quality alloys such as 18CrNiMo7-6 or 20MnCr5 are commonly picked. The Carburizing Edge: With careful heat treatment, carbon gets added to the surface, forming a tough outer layer (58–62 HRC) while keeping a flexible core that absorbs impacts (35–45 HRC). Tooth Micro-geometry and Precision Grinding To work at 15,000 RPM without too much racket, the tooth sides must be polished to a finish of Ra 0.4 or smoother. Precision Finishing: Modern CNC grinding cuts down on “transmission error,” which is the chief reason for steady noise in quick gearboxes. Micro-geometry Tweaks: Advanced setups use “crowning” and “tip relief”—tiny changes in microns—to spread loads evenly, even if shafts flex a bit under strong torque. Why Customized Engineering is the Key to Differentiation While basic gear sets are available, the most creative tool makers turn to customized designs to reach higher levels of torque and toughness. For a wider view of how the power tool field sets benchmarks, see the Power Tool Institute. The Limits of Off-the-Shelf Solutions Standard “catalog” gears often fall short of the tough goals for cutting weight or achieving no-play positioning in pro-level tools. A customized method lets designers: Adjust the gear ratio to match certain motor power patterns. Build for long-term use (like tools that handle over 200,000 cycles). Lower the tool’s total weight by picking special materials or slimming gear parts without losing strength. Customized Solutions for Specific Load Spectrums Each power tool has its own work pattern. A rotary hammer deals with heavy hits, while an electric screwdriver needs careful control and quiet running. By selecting a customized planetary gear system, makers can adjust the module (tooth size) and tooth shape to match power needs with low noise and vibration for precision tools. DD Gear: Your Partner for Precision At DD Gear, we do not keep a stock of ready-made parts. Instead, we concentrate only on customized, build-to-print jobs for worldwide OEMs in power tools, robotics, and EV areas. We focus on small-module precision planetary gears (usually m 0.3–0.8) and apply the latest Klingelnberg and Reishauer grinding tools to aim for ISO Grade 4–5 accuracy. If you need a sturdy precision planet gear for a pro grinder or a quiet helical-planetary stage for a smart automation device, our team offers full help from design and customized prototyping to large-scale production. Our dedication to quality comes with our ISO 9001 and IATF 16949 certified plants, so every precision gear delivers on reliability. Upgrade your power tools with custom precision planetary gears. Contact DD Gear to boost torque, efficiency, and reliability in your next design. FAQ Q: Why are planetary gears better than spur gears for power tools? A: Planetary gears spread torque over multiple planet gears, which allows for much higher torque density in a smaller, coaxial package. They also run more efficiently and more quietly at high speeds. Q: What materials are best for high-torque power tool gear sets? A: We mainly use high-load case-hardening steels like 18CrNiMo7-6 and 20MnCr5 to provide a wear-resistant surface (58-62 HRC) and a shock-absorbing core. Q: How do you ensure the gears won’t be too noisy in a handheld tool? A: We use precision grinding to aim for ISO Grade 4-5 accuracy and apply micro-geometry modifications like “tip relief” and “crowning” to minimize the vibrations that cause noise. Q: What is the typical efficiency of a planetary gear stage? A: A well-designed planetary gear mesh typically achieves between 94% and 99% efficiency, making them ideal for maximizing the battery life of cordless tools.

How Gear Design, Materials, and Standards Shape Performance

In the intense world of industrial automation, the gap between a machine that runs smoothly and one that breaks down badly often rests on the tiny precision of its gears. Current uses, like electric vehicle (EV) motors turning at 15,000+ RPM or robotic arms needing sub-micron positioning accuracy, put heavy demands on drivetrain parts. When regular stock items fall short of the needs for noise, vibration, and lasting strength, tailored precision work turns into the main choice. At DD Gear, we have focused for over 15 years on made-to-order, build-to-print precision gear manufacturing, supplying big makers worldwide in fields from humanoid robotics to electric passenger vehicles. Our goal stays firm: deliver gears that mix accuracy, toughness, and quiet running to push forward smart motion. Gear Design: Optimizing Geometry for Performance The shape of a gear sets how power moves and how the setup handles stress. For fast spins and strong twists, the planning stage matters a lot to cut down noise and stretch out working life. Tooth Profile and Engagement: Spur vs. Helical Picking the best tooth shape starts the whole gear design process: Spur Gears: Have straight teeth lined up with the axis. They work well (94–99%) and cost less for shafts that run side by side, but they can make a bump sound at quick speeds from quick tooth hits. Helical Gears: Have teeth sliced at a slant, which lets one tooth grab on before the last one lets go. This leads to much quieter work and bigger load handling, so custom helical gears stand as the usual pick for EV gearboxes and quick automation. Micro-geometry Tweaks for NVH Control To cut back more on Noise, Vibration, and Harshness (NVH), workers add certain changes to the tooth face: Crowning: Shaping the tooth surface so contact stays in the middle even when shafts bend under big twists. Tip Relief and Lead Correction: Taking off small bits at the tooth ends or tips to stop bangs and share forces evenly. Flank Polishing: A smoothed and shined tooth side drops friction waste, boosting drivetrain work by up to 1.2%. Compact High-Ratio Configurations Today’s robotics and Automated Guided Vehicles (AGVs) call for big drop ratios in small spots: Planetary Gear Sets: These give strong torque in a tight area by sharing the load over several planet gears, perfect for robot arms and AGV drive wheels. Harmonic Reducers: For custom robotic joints, these bring high-ratio drops (up to 320:1) with almost no play in a small, straight-line setup. Materials and Heat Treatment: The Science of Durability A gear tooth deals with huge bending pull at its base and smashing push at the contact line. Choosing the right metal mix and hardening method marks the difference between a gear that holds up one year and one that goes five. Specialized Case-Hardening Steels Top-performing gear groups often begin as shaped pieces of strong alloy steels: 18CrNiMo7-6 and 20MnCr5: These are used a lot in heavy-load custom helical gears because of their solid fight against wear-out and inner strength. 20CrMnTi: A common choice for CNC machine gears and power tools, giving a mix of wear resistance and hit toughness. Non-Magnetic Options: For medical scan gear, like drives near MRI tables, custom answers use aluminum bronze or austenitic stainless steels to keep things safe and clear in images. The Carburizing Advantage Carburizing adds carbon to the outer skin of the steel in a heat step: Dual-Property Structure: It builds a tough outer layer (58–62 HRC) to battle wear, while keeping a softer, stronger core (35–45 HRC) to take in quick hits without breaks. Consistency: At DD Gear, a tightly-managed process holds case depth in a 0.05 mm band, ensuring steady results over many units. For deeper facts on metal traits in gear making, check the American Gear Manufacturers Association (AGMA) for trusted rules known around the world. Standards and Accuracy: Defining Precision To keep things steady in round-the-clock warehouse moves or fast travel, gears need to get built and checked against tight global rules. ISO 1328 Grade 4 and 5 Precision Accuracy levels set the allowed slip in tooth shape, spacing, and slant: Grade 4/5: This sets the bar for robotics and EVs. Reaching Grade 4 keeps the shape slips under 4 µm, key for runs over 10,000 RPM. DD Gear Commitment: We use the newest Reishauer and Klingelnberg CNC grinders to aim for ISO Grade 4 accuracy or better for all custom jobs. Minimizing Transmission Error (TE) and Backlash Transmission error—the gap between the planned and real spot of a gear in turn—causes most gear hum. High-End Grinding: Getting a surface smooth to Ra 0.4 μm or finer helps meet tough NVH needs in passenger EVs. Backlash Control: In robotic joints, custom play gaps get held tight (often in a few arc-minutes) to stop loose moves, which can lead to robot shake and spot mistakes. Technical rules for round gears are kept and refreshed by the International Organization for Standardization (ISO), offering a shared way to talk about gear quality. Data-Driven Case Studies: Optimizing Performance Ideas turn real in actual use. Here come samples of how custom work at DD Gear fixed tough running issues. Case Study 1: Reducing NVH in a Passenger EV Reducer A new-energy vehicle maker dealt with a sharp whine at road speeds (80–110 km/h). The Problem: Regular helical gears in the two-stage reducer had built up slips that stirred up steady noise. The Solution: DD Gear supplied a custom helical gear set with 18CrNiMo7-6 steel and fine-tuned small shapes (crowning and end-relief). Result: A big drop in steady noise and better mesh work, helping cut energy use (kWh/100 km). Case Study 2: Stabilizing a Bipedal Humanoid Robot A robotics firm fought with balance because its joint drives had too much mechanical give. The Problem: Big play in standard planetary gearheads caused sway in steps. The Solution: We worked together on custom small-module planetary gears (sun, planet, and ring) with sub-micron tooth accuracy. Result: The joint loose motion dropped a lot, leading to even paths and steadier balance hold. Conclusion: The DD Gear Advantage Picking the best custom precision gear pays off over time in setup steadiness. While basic gears might work for plain belts, the calls of the “Future of Motion”—robotics, EVs, and smart automation—need a focused way. DD Gear brings high-precision gear answers fitted to your case, motor, and sound aims. We give: 15+ Years of Experience: Counted on by world makers and Fortune 500 firms. Fast Iteration: High-precision custom samples usually ship in 2–3 weeks. Certified Quality: Plants hold ISO 9001 and IATF 16949 marks to deliver steady top answers. FAQ Q: What is the primary cause of gear noise at high speeds? A: Small slips in tooth shapes, called transmission error, make teeth hit instead of slide easily, leading to a sharp hum. Q: Why are small-module gears necessary for modern robotics? A: Small-module gears (0.2–0.8 mm) let builders fit huge torque and big drop ratios into tight areas, like robot arms or humanoid joints. Q: Does DD Gear support prototyping for new designs? A: Yes. We handle small start orders and usually send custom samples in 2–3 weeks. Q: Which industries use DD Gear products? A: Our precision gears show up in humanoid robots, EV drivetrains, AGVs, medical imaging equipment, and high-speed CNC machinery.

LOVE TO HEAR FROM YOU GET IN TOUCH!

Please fill out the form below and we will get back to you as soon as possible.