- support@ddgear.com

- North 3F, Building 13-2, Zhixin Park, NO.1099 Xianhua South Street, Wucheng, Jinhua, Zhejiang, China.

Products

Robotic Elbow Gear

Product Details

FAQ

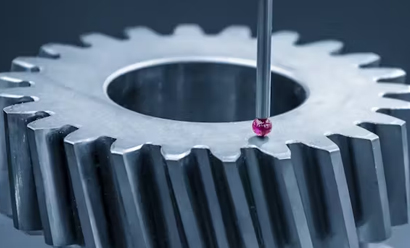

High Precision & Low Backlash

Manufactured to Grade 4 accuracy or better, our Joint Gear guarantees smooth joint operation with minimal play—critical for humanoid robot dexterity.

Durable Material & Treatment

Made from alloy steel with tailored carburizing and quenching, ensuring a hard, wear-resistant surface and tough core for extended lifespan.

Compact Design

Small-module configuration allows integration into tight joint assemblies without compromising torque performance.

Noise Reduction

Polished tooth surfaces and precision shaft fitting reduce vibration and noise—ideal for human-interactive robotics.

Lightweight & Efficient

Optimized for minimal inertia, reducing energy consumption and boosting movement responsiveness

Product parameters

Module:m0.5-m2

Material: 20CrMnTi/42CrMo (alloy steel)

Hardness: HRC 58-62(surface); ≥HRC 30 (core)

Tooth Accuracy: ISO Class 4 or better

Surface Finish:Ra≤0.8 μm

Outer Diameter: Customizable, range10-50mm

Bore Type: Straight, keyway, or spline (based on joint design)

Lubrication: Compatible with standard synthetic and silicone greases

Application areas/scenarios

Joint Gear is specifically tailored for humanoid robots—including companion bots, service robots, and rehabilitation devices. In one project with a leading robotics firm, our Joint Gear enabled a walking robot to perform precise balancing routines and dynamic hand gestures, significantly enhancing user interaction capabilities. The gear’s silent, accurate motion also improved perception of robotic “lifelikeness”—a crucial advantage in social robotics and customer-facing automation.

Q1: What makes your precision gears unique?

A1: DDGear’s precision gears stand out for their ultra-tight tolerances (ISO ≤ Class 4), hardened alloy material (e.g., 20CrMnTi, 42CrMo), micron-level surface finishes (Ra ≤ 0.8 µm), and superior wear resistance. They are optimized for minimal vibration and long service life, making them ideal for applications such as robotics, EV drivetrains, AGVs, and medical devices.

Q2: Can you customize gears to our exact specifications?

A2: Absolutely. We offer both OEM and ODM services—including design refinement, material selection, and tailored manufacturing. Our engineering team supports you from prototype to mass production, with flexible options for module, bore type, and heat treatment.

Q3: How long is the lead time for prototypes and production?

A3: For gears with existing tooling, typical lead time is around 15 days. For custom parts, sample production takes 2–3 weeks depending on complexity. We prioritize fast turnaround while ensuring top precision.

Q4: What quality standards and certifications do you adhere to?

A4: We operate under ISO 9001 and IATF 16949 quality systems and comply with ISO 1328, DIN, and AGMA standards. All gears go through SPC monitoring, CMM checks, noise/vibration testing, and full traceability documentation to ensure consistent performance.

Q5: What industries do you serve, and what makes your service reliable?

A5: DDGear serves over 30 countries and has collaborated with leading OEMs across robotics, EVs, AGVs, medical equipment, industrial automation, e-bikes, and automatic doors. Our in-house manufacturing capabilities—covering everything from design to production—ensure short delivery cycles, high quality, and flexible volume scaling.

Reliable precision gears for robotics, automotive, and beyond.

Sprockets

Sprockets are designed for reliable chain-driven transmission, ensuring efficient motion control in motorcycles, agricultural machinery, and industrial equipment.

Crown Wheel and Pinion

Crown wheels and pinions ensure efficient torque distribution and smooth power transfer in differential systems, delivering reliable performance for heavy-duty vehicles and precision machinery.

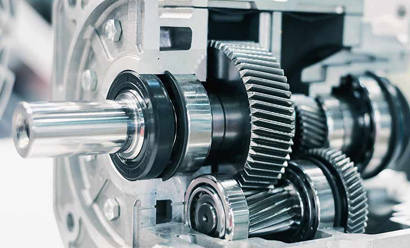

Helical Gear

Helical gears feature angled teeth for quieter operation and higher load capacity, making them ideal for electric vehicles, robotics, and industrial automation.

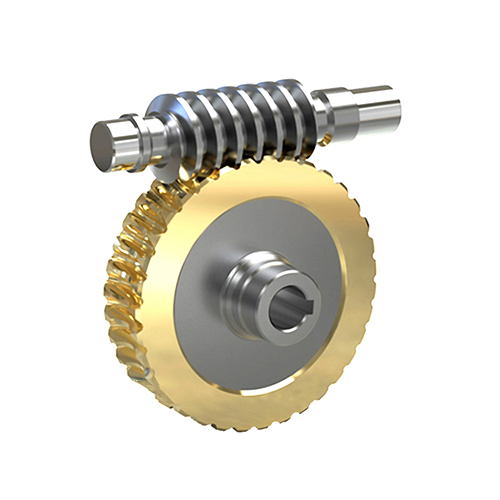

Worm Gear

Worm gears offer stable and secure transmission with self-locking properties, making them ideal for medical devices, automation systems, and precision control applications.Exploring The Science of Precision Gears

Quality Control in Precision Gear Manufacturing

Introduction Quality control is the backbone of precision gear manufacturing. For gears used in demanding applications such as robotics and EVs, consistent reliability is ensured only through a rigorous quality management system spanning design, production, and delivery. 1.Design Stage Control From profile optimization to material selection, all design elements are evaluated to ensure manufacturability, durability, and performance. 2.Process Control Real-time monitoring, statistical process control (SPC), and automated inspections are applied throughout machining to minimize deviations and maintain tolerances. 3.Final Inspection Profile and lead measurement Noise and vibration testing Endurance and wear verification These checks ensure that every gear meets both functional and quality standards. 4.Certifications & Standards Precision gears comply with global standards such as ISO 1328, DIN, and AGMA. Certified systems like ISO 9001 and IATF 16949 ensure consistent quality for international customers. Conclusion Strict quality control guarantees not only the accuracy and durability of precision gears but also builds long-term customer trust. By adhering to the highest global standards, precision gear manufacturers support the reliability of next-generation robotics, EVs, and intelligent automation.

Manufacturing Process of Precision Gears

Introduction Precision gears are not just the result of design excellence—they are the outcome of meticulous manufacturing. Every stage, from raw material to final inspection, determines the gear’s performance, durability, and accuracy. 1.Blank Preparation Gear blanks are typically made from forgings, castings, or bar stock. Material quality is the first guarantee of gear reliability. 2.Gear Cutting Hobbing: High efficiency, suitable for mass production. Shaping: Ideal for internal gears and complex profiles. Shaving: Improves tooth surface finish and precision. 3.Heat Treatment Processes such as carburizing, nitriding, and induction hardening are applied to enhance hardness, wear resistance, and durability. 4.Finishing Grinding: Achieves sub-micron tolerances. Polishing: Reduces roughness, minimizes noise. Finishing operations ensure smooth performance and precise accuracy. 5.Inspection & Testing Gears undergo profile and lead measurement, noise analysis, and endurance testing to guarantee consistent performance. Conclusion Manufacturing precision gears is a blend of science, engineering, and craftsmanship. By strictly controlling every process, manufacturers can deliver gears that meet the demanding standards of robotics, EVs, and industrial automation.

Application Fields of Small-Module Precision Gears

Introduction In today’s high-tech industries, gears remain at the heart of power transmission. Small-module precision gears, with their compact size and high accuracy, have become essential components in robotics, electric vehicles, medical devices, and automated logistics. Robotics Small-module gears are widely used in humanoid robot joints, collaborative robots, and industrial robots. They provide high-precision rotation and torque transfer in limited spaces, ensuring smooth and repeatable movements. Electric Vehicles In EV drive motors and two-speed gearboxes, small-module gears enable high-speed operation with low noise, improving energy efficiency and driving comfort. Medical Devices Medical devices demand stability and quiet operation. Small-module gears are applied in surgical robots, imaging equipment, and precision delivery systems. Automation & AGVs In AGVs and automated warehousing, small-module gears power lifting mechanisms and steering wheels, ensuring efficient and reliable material handling. Conclusion Small-module precision gears are driving the future of industries, providing a solid transmission foundation for next-generation robots, EVs, and intelligent systems

LOVE TO HEAR FROM YOU GET IN TOUCH!

Please fill out the form below and we will get back to you as soon as possible.