- support@ddgear.com

- North 3F, Building 13-2, Zhixin Park, NO.1099 Xianhua South Street, Wucheng, Jinhua, Zhejiang, China.

Robot

Harmonic Reducer Gear – Precision Gear Set for Robot | DD Gear

The Harmonic Reducer Gear – High Precision Gear Set for Robot Joints is a custom strain-wave gear component set designed for compact, high-ratio robotic actuators. In a typical harmonic reducer, three core elements work together: a wave generator, a thin-walled flexspline with external teeth, and a rigid circular spline with internal teeth and usually two more teeth than the flexspline. As the wave generator deforms the flexspline into an elliptical shape and rotates, the flexspline teeth engage the circular spline at two opposite regions; because of the tooth-count difference, one full rotation of the wave generator makes the flexspline advance only a few teeth in the opposite direction, delivering very high single-stage reduction ratios (roughly 30:1 to 320:1) in a compact, coaxial package with near-zero backlash. DD Gear focuses on small-module, high-precision gears for robotics and automation, supplying flexspline and circular spline gear components according to customer drawings rather than complete branded harmonic drive units. By combining fine-pitch tooth cutting, appropriate materials and heat treatment for high contact stress, and tight control of internal/external gear accuracy, DD Gear helps robot and actuator manufacturers achieve the torque density, stiffness, and positioning accuracy required in humanoid robots, collaborative arms, SCARA robots, AGV wheel modules, and other precision motion systems where harmonic reducers are the preferred solution.Planetary Reducer Gear – Precision Gear for Robot | DD Gear

The Planetary Reducer Gear – High Precision Gear Set for Robot Actuators is a custom gear component set used in planetary (epicyclic) reducers for servo motors and robotic joints. A typical planetary reducer consists of a central sun gear, multiple planet gears, an internal ring gear, and a carrier that holds the planets. The planets orbit around the sun while meshing with the fixed or rotating ring, so torque is transmitted through several teeth at once. This architecture delivers high torque in a compact, coaxial layout with input and output on the same axis, and offers excellent torque-to-size ratio and efficiency compared with many other in-line gear trains. In robotics and automation, high-precision planetary reducers are widely used as servo gearheads and joint reducers because they combine compact size, high torque density, and low backlash when designed with ground gears, preloaded bearings, and optimized tooth profiles. They are particularly suitable where space is limited but precise motion control is required, such as in robot arms, collaborative robots, AGV drive units, and positioning stages. DD Gear focuses on small-module, high-precision gears, supplying custom sun, planet, and ring gears for planetary reducers according to customer drawings and specifications, so that actuator and robot manufacturers can reach their target torque, stiffness, and positioning accuracy with a build-to-print gear solution.Precision Gears Built for the Future.

Trusted by Global OEMs, Proven in Every Application.

Your Custom Gear Solution Starts Here.

LOVE TO HEAR FROM YOU GET IN TOUCH!

Exploring The Science of Precision Gears

How Gear Design, Materials, and Standards Shape Performance

In the intense world of industrial automation, the gap between a machine that runs smoothly and one that breaks down badly often rests on the tiny precision of its gears. Current uses, like electric vehicle (EV) motors turning at 15,000+ RPM or robotic arms needing sub-micron positioning accuracy, put heavy demands on drivetrain parts. When regular stock items fall short of the needs for noise, vibration, and lasting strength, tailored precision work turns into the main choice. At DD Gear, we have focused for over 15 years on made-to-order, build-to-print precision gear manufacturing, supplying big makers worldwide in fields from humanoid robotics to electric passenger vehicles. Our goal stays firm: deliver gears that mix accuracy, toughness, and quiet running to push forward smart motion. Gear Design: Optimizing Geometry for Performance The shape of a gear sets how power moves and how the setup handles stress. For fast spins and strong twists, the planning stage matters a lot to cut down noise and stretch out working life. Tooth Profile and Engagement: Spur vs. Helical Picking the best tooth shape starts the whole gear design process: Spur Gears: Have straight teeth lined up with the axis. They work well (94–99%) and cost less for shafts that run side by side, but they can make a bump sound at quick speeds from quick tooth hits. Helical Gears: Have teeth sliced at a slant, which lets one tooth grab on before the last one lets go. This leads to much quieter work and bigger load handling, so custom helical gears stand as the usual pick for EV gearboxes and quick automation. Micro-geometry Tweaks for NVH Control To cut back more on Noise, Vibration, and Harshness (NVH), workers add certain changes to the tooth face: Crowning: Shaping the tooth surface so contact stays in the middle even when shafts bend under big twists. Tip Relief and Lead Correction: Taking off small bits at the tooth ends or tips to stop bangs and share forces evenly. Flank Polishing: A smoothed and shined tooth side drops friction waste, boosting drivetrain work by up to 1.2%. Compact High-Ratio Configurations Today’s robotics and Automated Guided Vehicles (AGVs) call for big drop ratios in small spots: Planetary Gear Sets: These give strong torque in a tight area by sharing the load over several planet gears, perfect for robot arms and AGV drive wheels. Harmonic Reducers: For custom robotic joints, these bring high-ratio drops (up to 320:1) with almost no play in a small, straight-line setup. Materials and Heat Treatment: The Science of Durability A gear tooth deals with huge bending pull at its base and smashing push at the contact line. Choosing the right metal mix and hardening method marks the difference between a gear that holds up one year and one that goes five. Specialized Case-Hardening Steels Top-performing gear groups often begin as shaped pieces of strong alloy steels: 18CrNiMo7-6 and 20MnCr5: These are used a lot in heavy-load custom helical gears because of their solid fight against wear-out and inner strength. 20CrMnTi: A common choice for CNC machine gears and power tools, giving a mix of wear resistance and hit toughness. Non-Magnetic Options: For medical scan gear, like drives near MRI tables, custom answers use aluminum bronze or austenitic stainless steels to keep things safe and clear in images. The Carburizing Advantage Carburizing adds carbon to the outer skin of the steel in a heat step: Dual-Property Structure: It builds a tough outer layer (58–62 HRC) to battle wear, while keeping a softer, stronger core (35–45 HRC) to take in quick hits without breaks. Consistency: At DD Gear, a tightly-managed process holds case depth in a 0.05 mm band, ensuring steady results over many units. For deeper facts on metal traits in gear making, check the American Gear Manufacturers Association (AGMA) for trusted rules known around the world. Standards and Accuracy: Defining Precision To keep things steady in round-the-clock warehouse moves or fast travel, gears need to get built and checked against tight global rules. ISO 1328 Grade 4 and 5 Precision Accuracy levels set the allowed slip in tooth shape, spacing, and slant: Grade 4/5: This sets the bar for robotics and EVs. Reaching Grade 4 keeps the shape slips under 4 µm, key for runs over 10,000 RPM. DD Gear Commitment: We use the newest Reishauer and Klingelnberg CNC grinders to aim for ISO Grade 4 accuracy or better for all custom jobs. Minimizing Transmission Error (TE) and Backlash Transmission error—the gap between the planned and real spot of a gear in turn—causes most gear hum. High-End Grinding: Getting a surface smooth to Ra 0.4 μm or finer helps meet tough NVH needs in passenger EVs. Backlash Control: In robotic joints, custom play gaps get held tight (often in a few arc-minutes) to stop loose moves, which can lead to robot shake and spot mistakes. Technical rules for round gears are kept and refreshed by the International Organization for Standardization (ISO), offering a shared way to talk about gear quality. Data-Driven Case Studies: Optimizing Performance Ideas turn real in actual use. Here come samples of how custom work at DD Gear fixed tough running issues. Case Study 1: Reducing NVH in a Passenger EV Reducer A new-energy vehicle maker dealt with a sharp whine at road speeds (80–110 km/h). The Problem: Regular helical gears in the two-stage reducer had built up slips that stirred up steady noise. The Solution: DD Gear supplied a custom helical gear set with 18CrNiMo7-6 steel and fine-tuned small shapes (crowning and end-relief). Result: A big drop in steady noise and better mesh work, helping cut energy use (kWh/100 km). Case Study 2: Stabilizing a Bipedal Humanoid Robot A robotics firm fought with balance because its joint drives had too much mechanical give. The Problem: Big play in standard planetary gearheads caused sway in steps. The Solution: We worked together on custom small-module planetary gears (sun, planet, and ring) with sub-micron tooth accuracy. Result: The joint loose motion dropped a lot, leading to even paths and steadier balance hold. Conclusion: The DD Gear Advantage Picking the best custom precision gear pays off over time in setup steadiness. While basic gears might work for plain belts, the calls of the “Future of Motion”—robotics, EVs, and smart automation—need a focused way. DD Gear brings high-precision gear answers fitted to your case, motor, and sound aims. We give: 15+ Years of Experience: Counted on by world makers and Fortune 500 firms. Fast Iteration: High-precision custom samples usually ship in 2–3 weeks. Certified Quality: Plants hold ISO 9001 and IATF 16949 marks to deliver steady top answers. FAQ Q: What is the primary cause of gear noise at high speeds? A: Small slips in tooth shapes, called transmission error, make teeth hit instead of slide easily, leading to a sharp hum. Q: Why are small-module gears necessary for modern robotics? A: Small-module gears (0.2–0.8 mm) let builders fit huge torque and big drop ratios into tight areas, like robot arms or humanoid joints. Q: Does DD Gear support prototyping for new designs? A: Yes. We handle small start orders and usually send custom samples in 2–3 weeks. Q: Which industries use DD Gear products? A: Our precision gears show up in humanoid robots, EV drivetrains, AGVs, medical imaging equipment, and high-speed CNC machinery.

Custom Gears: Key Industries Driving Demand for Tailored Solutions

In the quickly changing field of industrial automation, machines today must run faster, handle bigger loads, and fit into tighter spaces. Inside these complex systems, the behavior of one precision cylindrical gear can decide if everything works quietly and accurately or ends in a serious breakdown. When regular off-the-shelf parts fail to meet the strict needs for cutting noise, controlling vibration, and lasting many years, only custom precision gears tailored for specific applications provide a reliable solution. provide a reliable answer. The Rise of Customized Engineering in High-Performance Sectors Standard gears often reach their limits in special applications. This simple fact pushes the strong demand for custom precision helical gears and similar tailored parts. DD Gear concentrates on build-to-print custom projects. We produce precision small-module gears made for particular torque levels, limited housing room, and set noise limits. Through custom engineering, builders can adjust tooth flank features—such as crowning and tip relief—for smoother power transfer and much longer gear life. Electric Vehicles (EV): Precision for Efficiency and Silent Operation The electric vehicle sector drives the growing need for high-precision gears that enhance electric vehicle drivetrain gears, improving drivetrain efficiency while reducing noise.Electric cars have no loud engine sound to hide problems, so gear whine and tonal noises stand out clearly to drivers and passengers. Overcoming Noise, Vibration, and Harshness (NVH) Motors in electric vehicle drivetrains frequently turn at 12,000–18,000 RPM. Under those conditions, a tooth profile error of just a few microns can create a sharp whine. Custom helical gears solve this problem well. Their angled teeth mesh step by step, spreading the load and cutting vibration a lot. Customized EV Transmission Components DD Gear offers several custom parts for EV drivetrains: Input Shafts: Built for steady operation at high speeds, these connect the electric motor to the gearbox first. Main Reduction Gears: They change high motor torque into torque at the wheels, affecting fast starts and overall battery use. Parking End Gears: Custom-made to resist strong shocks while keeping exact tooth spacing for safe locking. Intermediate Drive Shafts: Shaped to manage sudden torque spikes and stay in line to lower torque steer. By grinding custom gears aim to upgrade ISO levels, EV builders can gain up to 1.2% better drivetrain efficiency. For details on worldwide gear standards, visit the ISO. Robotics and Humanoid Joints: Zero-Backlash and Compact Power For robotics and humanoid joints, zero-backlash gears for robotics are required, providing high-precision planetary gears that ensure minimal play and consistent torque density in compact spaces. Achieving Micron-Level Positioning Accuracy A robot arm often places parts with repeatability of ±0.02 mm. Any play or backlash in the gear train causes obvious wobbles and path mistakes. Custom zero-backlash gears are necessary for steady control in joints like hips, knees, and elbows. Customized Solutions for Robotic Actuators To reach large reduction ratios up to 320:1 in a space the size of a coffee cup, custom gear sets are required. Harmonic Reducer Components: DD Gear supplies custom flexsplines and circular splines for big single-stage reductions. Planetary Gear Sets: These work as servo gearheads, providing high torque density and low backlash with custom sun, planet, and ring gear shapes. Small-module gears from 0.2 mm to 0.8 mm allow these ratios to fit inside slim actuator housings. Automated Guided Vehicles (AGVs) and Logistics: 24/7 Durability In nonstop warehouse operations, AGVs and Autonomous Mobile Robots go through tough daily routines. Handling Frequent Start-Stop Cycles and Shock Loads Custom gear sets for AGVs are built to endure shock loads of 400–600 Nm, offering durable gears for high-speed applications and ensuring reliability during high-frequency operations in logistics. Standard gears usually develop early pitting and surface damage in such hard use. Customized AGV Drivetrain Systems DD Gear makes custom AGV gears from case-hardened alloy steels like 18CrNiMo7-6 or 20MnCr5. The custom heat treatment forms a hard outer layer at 58–62 HRC to resist wear. The core stays tougher at 35–45 HRC to handle sudden impacts. This setup delivers three to five years between maintenance stops, even in busy logistics areas. Machine Equipment and Industrial Automation For precision gears for CNC machines, custom helical gears for power tools and industrial automation gear solutions ensure high-speed timing and minimal backlash, improving manufacturing process efficiency. High-Speed Stability in CNC Machining CNC spindles and feed gearboxes require very low backlash and high stiffness for fine surface finishes. Switching from standard spur gears to custom small-module helical gears improves gear life by 30% and significantly reduces operational noise. Coordination in Packaging and Textile Machinery Packaging Machinery: Custom gears keep film feeds, sealing jaws, and filling steps in perfect sync in nonstop plants. Textile Machinery: Precision custom gears time multiple rollers and spindles to stop yarn breaks or fabric marks. Many engineers look to the AGMA for accepted gear design and accuracy rules. Power Tools and Specialized Applications Custom high-torque gear designs are essential in handheld tools and building systems, where compact spaces and high performance are required. Compact Strength for Handheld Drills and Grinders Custom gearheads for power tools, including spiral bevel and helical stages, provide high torque while reducing vibration for improved user comfort. Safety and Performance in Automatic Doors and E-Motorcycles Automatic Doors: Custom worm and helical stages give strong start torque and self-locking for safety in crowded buildings. E-Motorcycles: Custom planetary hub-motor sets or mid-drive helical stages deal with high electric motor speeds for smooth city rides. The DD Gear Advantage: Mastering Precision Gearing DD Gear is a focused producer of custom precision gears for high-performance applications with more than 15 years of experience. We work only on build-to-print jobs for worldwide OEMs in robotics, EV, and automation areas. Manufacturing Excellence: We use modern Reishauer and Klingelnberg CNC grinders to aim for ISO Grade 4 accuracy or better. Quality Control: Every gear gets full checks on CNC measuring machines and noise chamber tests before shipping. Fast Iteration: We aid quick product cycles by delivering high-precision prototypes in 2–3 weeks. Conclusion The move to faster speeds, smaller spaces, and quieter running has left standard gears behind in many advanced fields. From custom precision gears for electric vehicles to small-module gears for robotics and custom gear sets for AGVs, these tailored solutions are central to modern engineering performance. By matching tooth design to exact load, speed, and setting demands, custom gear parts from DD Gear keep future machines running smoothly and dependably. FAQ Q: What is the primary cause of gear noise at high speeds? A: Gear noise usually comes from transmission error caused by tiny tooth flank shape flaws. At speeds over 10,000 RPM, deviations of a few microns can produce a clear high-pitched whine. Q: Why are small-module gears required for modern robotics and EVs? A: Small-module gears help designers fit large torque and high reduction ratios into very small spaces, stopping the gearbox from taking too much room in the machine. Q: What level of accuracy can DD Gear guarantee for customized projects? A: For critical/high-performance applications, we can achieve up to ISO 1328 Grade 4–5 accuracy, verified on CNC gear measuring machines, according to each project’s specification. Q: Does DD Gear support small-volume customized orders for prototypes? A: Yes. We accept flexible small quantities and can usually ship high-precision custom prototypes within 2–3 weeks.

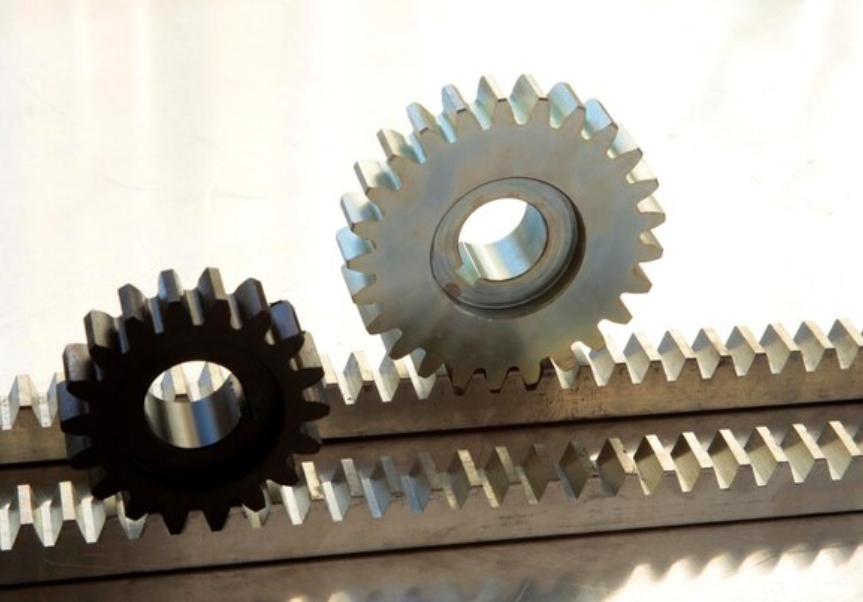

Why Precision Gear Racks Are Essential for Optimal Performance

In today’s fast-paced world of industrial gear systems and automation, small measurements often decide if a system runs at its best or breaks down. Electric motors commonly hit speeds from 12,000 to 18,000 rpm now. This creates a strong need for parts that turn that power into exact straight-line movement. Picture a robot arm stopping precisely or a warehouse cart pulling heavy loads. The basic mechanical parts underneath control how well everything works. At DD Gear, we know that machines today pack tighter and run quicker than before. High accuracy forms the key to dependable operation. The Evolution of Linear Motion in Industrial Automation The drive for quicker tasks and tight control has changed how people think about linear drive systems and gear rack drives. Older setups often had trouble with noise and wear when run hard. Current systems, though, need accuracy levels that cut down on costly repairs and lost power. Small-Module Precision: Factories and warehouses today demand precision gear sets that take heavier loads in smaller spaces. This calls for top-quality small-module precision gears. High-Density Operation: Tight drives in robot joints or CNC paths may require big speed drops inside areas just 80 mm across. Heat Management: Constant fast running builds friction. Oil in a electric vehicle gearbox can reach 120 °C quickly, so parts must handle hot conditions well. Core Mechanisms: Why Precision Racks Define Performance Straight motion results come down to how the gear pinion and gear rack work together. Poor control at this spot leads to transmission error (TE). That error then causes wider problems across the machine. Minimizing Transmission Error and NVH Fast automated setups react strongly to tiny gear tooth shape differences. Flaws just microns large can produce clear noise, vibration, and rough feel (NVH). Gradual Engagement: Helical gears mesh bit by bit to spread force. Precision straight parts follow the same idea to reduce noise and shaking a lot. Micro-Geometry Fixes: Fine grinding adds small adjustments to tooth edges, like tip relief, crowning, and root easing. These keep contact steady even when the shafts flex under torque around 300–400 Nm. Surface Finish: Reaching Ra 0.4 μm or better matters for tough NVH rules in electric cars and automation work. Controlling and Eliminating Backlash For robot joints or CNC gear drives, no backlash is vital to keep positioning the same every time and motion steady. Repeatable Positioning: A robot arm placing a screw within 10 microns has no room for loose play. Torsional Stiffness: Quality parts fight twisting. This holds joints solid as loads shift and stops the wobble common in cheaper drives. Lost Motion: Cutting lost motion means control signals reach the end without getting stuck in mechanical slack. Material Science and Durability Standards The toughness of a linear gear system rests on metal quality and careful heat treating. A part that wears out after months of nonstop use creates risks that factories avoid. For more on how strong materials affect part life, look at the materials from Gleason, a top name in gear studies. Case-Hardened Alloy Steels for 24/7 Duty To handle repeated starts and stops plus big shocks (like 400–600 Nm at the gear wheel), special metals are needed. 18CrNiMo7-6 Alloy: Makers choose this steel for heavy jobs. It gives a hard outside (62–64 HRC) against wear and a flexible core for impacts. Carburizing Consistency: Good control keeps case depth steady within 0.05 mm. This can stretch a part of life from one year to three or five. Fatigue Resistance: High-grade hardened steels often add 25–35% to service time before wear shows up. Achieving ISO Grade 4 Accuracy Accuracy means real measured standards, not just words. Reaching ISO 1328 Grade 4 gear accuracy requires very close limits. Profile Tolerance: Shape errors must stay below 4 µm. Lead and Pitch: Lead errors under 6 µm and pitch under 5 µm support speeds over 10,000 rpm. Efficiency Gains: Lifting a part from Grade 7-8 to 4-5 can raise efficiency by 0.6–1.2%. Over big operations, this saves noticeable energy. Application Scenarios: Where Precision is Non-Negotiable Accuracy needs change by field, but in critical work, it decides the final quality. You can find more engineering rules and standards for these setups at the National Institute of Standards and Technology (NIST). High-Speed CNC Machinery and Feed Systems CNC lathes and machining centers use precision gear racks for the spindle and feed boxes. Any mistake shows up as a poor surface finish or misaligned patterns. Positioning Accuracy: Today’s CNC tools need repeat placement around ±0.02 mm. Reducing Stoppages: Fine helical setups can cut gearbox breakdowns by up to 50%. Robotics and Automated Guided Vehicles (AGVs) AGV precision gear systems in busy warehouses face tough daily runs. They start and stop thousands of times per shift. Shock Load Management: These carts pull 1–2 tons and take sudden jolts that would ruin standard parts. Torque Density: Planetary and special straight stages often join to pack high turning force into small spaces, sometimes the size of a coffee cup. The DD Gear Advantage: Excellence in Customized Engineering At DD Gear, we avoid general solutions. We build custom precision gear racks focused on the exact noise, speed, and torque needs of our customers. Customized Design: We make parts to exact drawings with no off-the-shelf items. This fits your motor and housing just right. Fast Prototyping: Our staff can draw, build samples, and send custom test pieces in 2–3 weeks for quick checks on new ideas. Global Standards: Sites follow ISO 9001 and IATF 16949 rules. For critical/high-performance applications, we can achieve up to ISO 1328 Grade 4–5 accuracy using modern Höfler and Klingelnberg CNC grinders. Conclusion Do you need precision gear racks? It depends on your goals. If your setup calls for quiet running at 15,000 rpm, movement correct to a few microns, or strength for years of constant work, high accuracy is the practical path. Through custom building and top material choices, makers create bases for automated machines that do more than work – they lead the field. For broader applications beyond automation, PairGears supplies reliable gear solutions for agriculture, trucks, and construction machinery worldwide. FAQ Q: What is the main cause of noise in high-speed gear rack systems? A: The primary cause is transmission error (TE) resulting from minute shape deviations on the tooth flank. Even deviations of a few microns can cause significant whine at high speeds. Q: Why does DD Gear emphasize customized gear racks manufacturing over stock parts? A: Because high-performance systems for EVs, robots, and AGVs have unique constraints regarding space, torque, and NVH. Customized solutions ensure every micron of accuracy is optimized for the specific application. Q: What materials are best for high-cycle industrial environments? A: We typically use case-hardened alloy steels like 18CrNiMo7-6. These provide a hard exterior (62–64 HRC) to fight wear and a tough interior to absorb shock loads. Q: How does ISO Grade 4 accuracy affect energy efficiency? A: Moving from Grade 7-8 to Grade 4 can improve efficiency by up to 1.2%, which translates into more range for EVs or lower electricity costs for automated factories.

Choosing the Best Materials for Custom Gears

In the demanding field of industrial automation and electric vehicle drivetrains, a precision gear does much more than transfer power. It forms the basic building block for turning motion smoothly. Electric motors often run at input speeds of 12,000 to 18,000 rpm. This puts huge stress on high-torque gears. At such high rates, even a slight material weakness or wrong metal pick can cause quick wear, loud noise, or total breakdown. Good gear design starts with the right metal choices. The material decides how well a gear handles bending stress at the tooth base and pressure stress along the contact line. For a company like DD Gear, reaching top results comes from picking alloys and heat treatments that fit the exact torque, speed, and working conditions of each job. The Science of Metallurgy in Precision Gearing Picking the correct material is about finding the right mix for custom gears, not just going for the hardest one. A precision gear needs a tough outer layer to fight constant rubbing. Yet the inside must stay flexible enough to take sudden jolts without breaking. Understanding Case-Hardening Dynamics Many heavy-use high-torque gears rely on case-hardening alloy steels. These create two different layers in the metal. The Hardened Case: Methods like carburizing and quenching push the surface hardness to 60–64 HRC. This outer skin stands up to wear and stops pitting during nonstop running. The Tough Core: The surface stays very hard, but the center holds at around 35–45 HRC. This lets the precision gear absorb big shocks, like the 400–600 Nm forces in Automated Guided Vehicles (AGVs) when they stop fast. The Impact of Grain Structure on Fatigue Life Metal quality begins early, when the blank is shaped. High-end custom precision gears often start as forged pieces instead of plain bar metal. Forging aligns the grain flow along the tooth shape. This boosts strength against repeated stress a great deal. For more details on how metal fatigue shortens part life, look at the articles from Machine Design. They cover alloy behavior in depth. High-Performance Alloy Steels: A Comparative Overview Each job calls for its own gear material makeup. The table below lists the main steels used in custom precision gear work: Material Grade Primary Characteristics Common Applications 18CrNiMo7-6 High load capacity, excellent core toughness, and high nickel content. EV main reduction gears, high-torque planetary stages. 20MnCr5 Economical, good carburizing properties, stable heat treat. Robotic joint gears, AGV drive units. SCM415/ SCM420 High wear resistance, good for small-module precision. E-motorcycle reducers, power tool gearheads. 17CrNiMo6 Similar to 18CrNiMo, it is designed for extreme durability. Heavy-duty industrial automation, e-axles. Stainless Steel Corrosion resistance, non-magnetic options available. Medical imaging equipment, surgical robotics. Application-Specific Material Strategies A custom method means matching the metal to how the machine runs. Electric Vehicles and NVH Sensitivity In electric vehicle gearboxes, there is no engine noise to cover drivetrain gear sounds. Whine from the drivetrain stands out. Studies from places like Gleason show that transmission error causes most of the steady tones. 18CrNiMo7-6 stands out as the top choice. It allows fine grinding after heat treating to reach ISO 1328 Grade 4 accuracy. This steel works well with thin oils that raise efficiency. Those oils need very smooth tooth faces (Ra 0.4 μm or better) to stop tiny surface damage. Robotics and Torsional Stiffness Robot joints demand no play and strong resistance to twisting. This keeps the end tool from drifting. Small-module precision gears (usually 0.3–0.8 module) in these joints use metals that fight bending under shifting loads. Custom planetary gears for robots often pick 20MnCr5 for torsional stiffness. It helps the gears stay stiff and repeat positions over millions of moves. Medical Equipment and Non-Magnetic Requirements Devices like MRI machines need non-magnetic gears that do not affect magnetic fields. Custom work for these areas turns to non-magnetic metals such as aluminum bronze, brass, or austenitic stainless steels. These metals are softer than alloy steels. Special coatings like nitriding add wear protection without the shape changes from hot quenching. Advanced Treatments: Beyond the Base Metal The starting metal is important, but the final steps shape how well custom precision gears perform. Nitriding vs. Carburizing Carburizing: Best for heavy loads in AGVs and EVs. It builds deep, hard layers (up to 1.2 mm) for shock handling. Nitriding: Better for fine accuracy jobs where shape change must stay low. Lower heat keeps tolerances tight without the bending seen in usual quenching. Surface Finishing for Efficiency Switching to ground and polished gear teeth can lift drivetrain efficiency by 0.6% to 1.2%. For a group of electric delivery vans, that small boost adds real distance on each battery charge. The DD Gear Advantage: Excellence in Customized Engineering At DD Gear, we have built over 15 years of skill in making small, high-accuracy gears. We know every tiny measurement and metal decision counts. Customized Build-to-Print: We avoid stock items. Each precision gear set comes from your drawings, run cycles, and noise goals. Global Standards: Our shops follow IATF 16949 and ISO 9001 rules. For critical applications, DD Gear can achieve up to ISO 1328 Grade 4–5 accuracy, verified on Klingelnberg P26/P40 gear measuring machines. Rapid Validation: We help new companies and big makers with quick custom samples, often sent in 2–3 weeks. Advanced Inspection: All gears go through full checks on Klingelnberg P26 or P40 machines. This confirms a steady tooth shape and lead. Conclusion Do all gears need top-grade materials? Not always. But in fast, crowded systems where downtime costs big, the metal forms the base of everything. With custom gear alloys and careful heat processes, builders create machines that run quieter, last longer, and move with the exactness today’s work requires. FAQ Q: Why is 18CrNiMo7-6 preferred for EV gearboxes? A: This alloy provides an exceptional balance of surface hardness and core toughness, which is necessary to handle the high input speeds (up to 18,000 rpm) and high torque of electric motors while maintaining low noise levels. Q: How does DD Gear ensure the accuracy of customized gear materials? A: For critical applications, DD Gear can achieve up to ISO 1328 Grade 4–5 accuracy, verified on Klingelnberg P26/P40 gear measuring machines. Inspection plans combine 100% checks on key features with batch-level validation according to each project’s risk and quality requirements. Q: Can you provide customized gears in non-magnetic materials? A: Yes. For medical and MRI applications, we offer customized solutions using aluminum bronze, brass, and austenitic stainless steels to ensure zero magnetic interference. Q: What is the typical lead time for customized prototypes? A: We pride ourselves on fast reaction times, generally delivering customized prototype gears within 2–3 weeks to help you validate your designs quickly.

Driving Precision Forward with

Custom gear solutions

Please fill out the form below and we will get back to you as soon as possible.